Would You Like Some Chocolate With That Hairnet?

Ever on the hunt for fun things to do with our tribe, the whole lot of us headed to a local Nashville chocolate company, Olive & Sinclair to see how they hand-make delicious chocolate products (and gummy bears).

As is often the case, a tour of a food factory begins with a hairnet.

I was hopeful that Eddie would have to put on a beard-net, but that didn’t happen. I may pay extra for that next time.

After we were netted up, we headed back to learn the process. The company employs 10 folks, which includes 3 full-time “wrappers.”

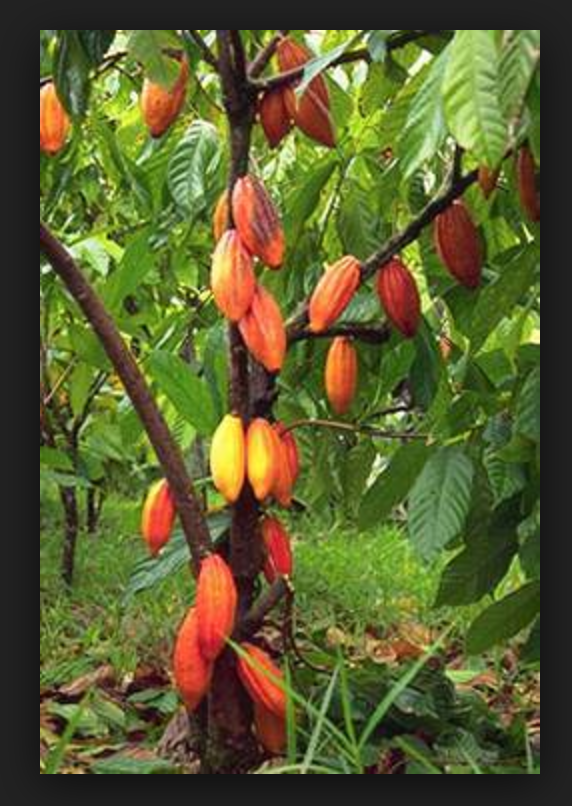

Our guide walked us through the entire process. We were surprised to learn the cocoa pods grow on the trunk and branches of the tree.

Olive & Sinclair breaks down the pods to get to the beans inside, which they divide up into 25 pound buckets for easier dumping.

The picture above shows a dried pod with a bowl of cocoa beans. The beans are roasted in their huge roaster, 75 pounds at a time, and then cracked to get to the nibs inside, which are what they use to make the chocolate products.

Our guide cracked a roasted bean, which broke like a coffee bean, so we could each try a bit of plain nib. It was interesting to try, but few of us were fans.

After the nibs are shelled (This is done mechanically at O & S, but our guide told us of a chocolate company who has that part done by hand, just to provide more jobs for folks.), they are taken to the stone grinders. One is for the brown chocolate grinding, the other has their white chocolate grinding done in it.

Up to this point, I’ve been impressed with my memory of the tour. That breaks down going forward.

After the chocolate nibs have been ground smooth, the creamy goodness (That actually tastes like peanut butter when you put a sample in your mouth, but quickly turns bitter.) is hand scooped out of the stone bin to continue the process.

From here, things get made. I listened during the tour, but began to lose focus.

I do remember sampling their Bourbon Nib Brittle. That was memorably delicious.

O & S products are for a sophisticated palate. Their white chocolate bar is seasoned with salt and pepper. The caramels come in two flavors: duck fat and sea salt and vinegar. The children were not completely impressed, although they all sampled various items, and Yessa tried the cherry cordial that T shared with her. T’s Dad is a huge fan of chocolate-covered cherries, so she bought out the remaining cherries to take home to him for Christmas.

We purchased an assortment of products to try, and then headed back to our house for a chili dinner and playing and visiting.

I love this crowd.